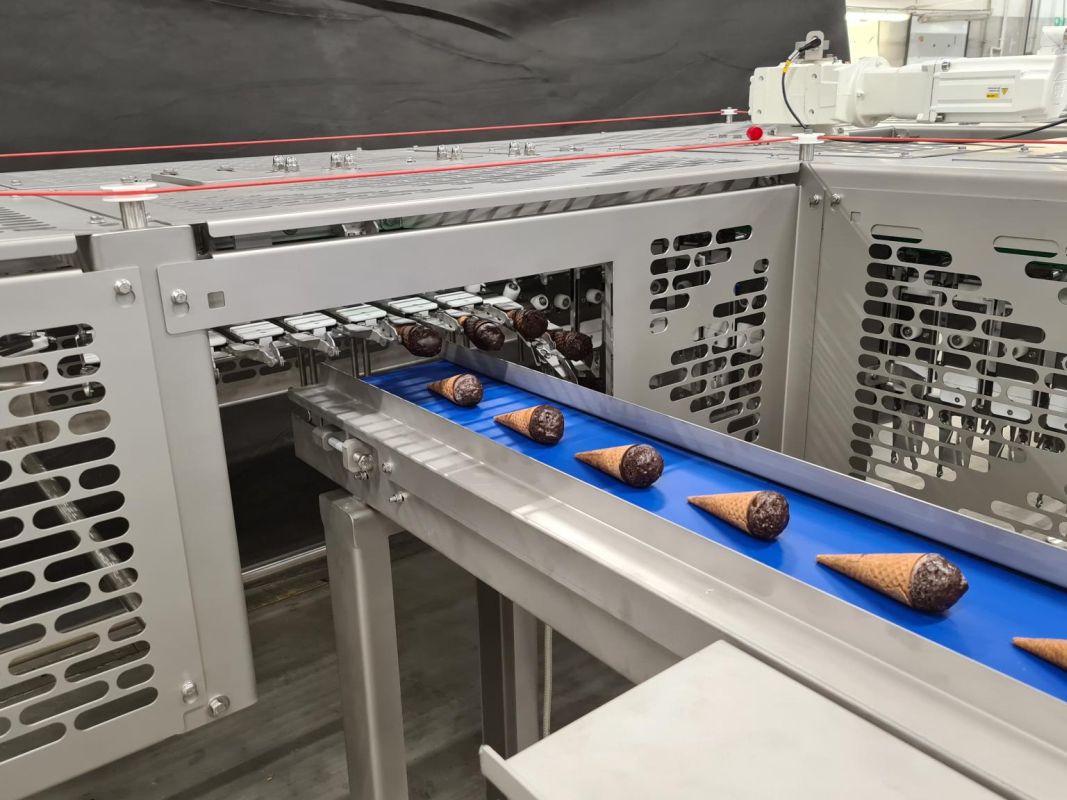

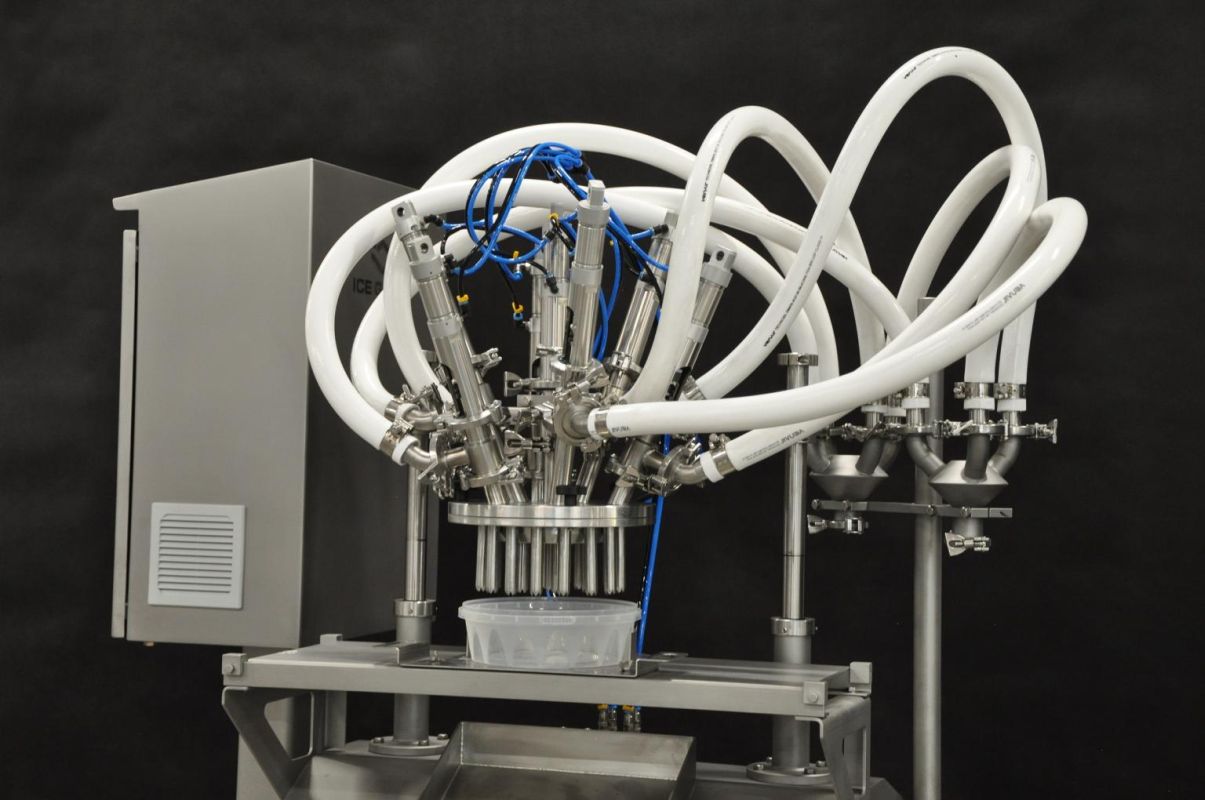

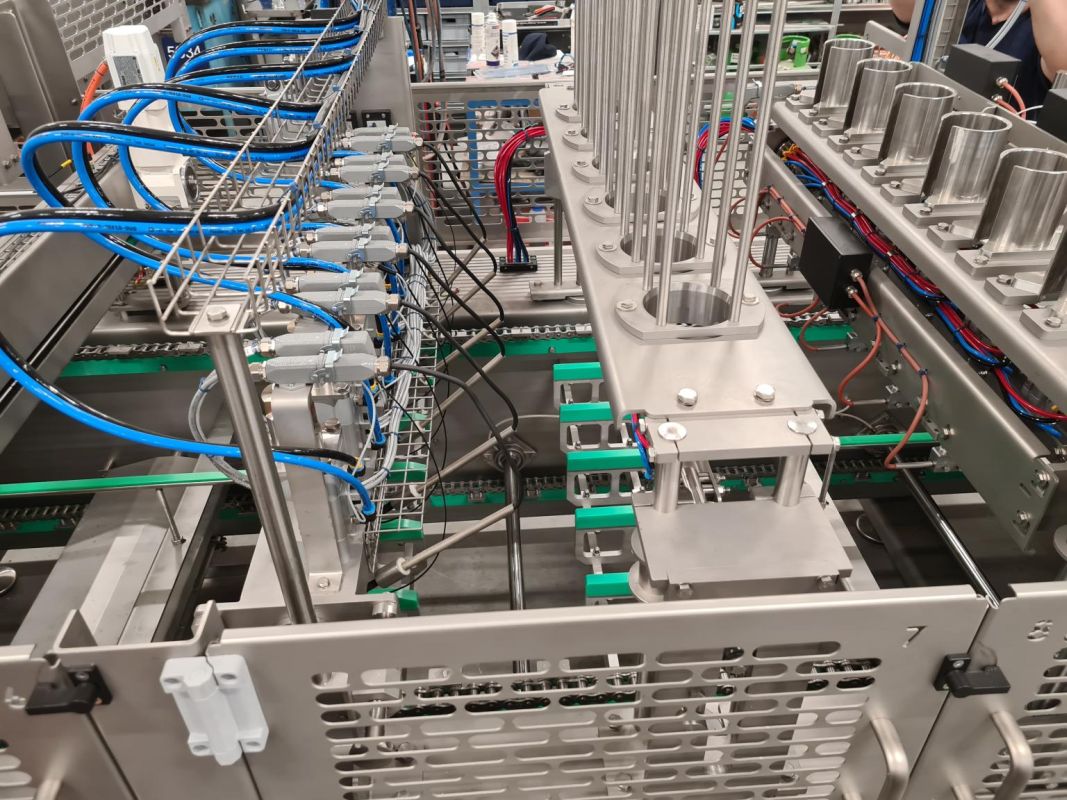

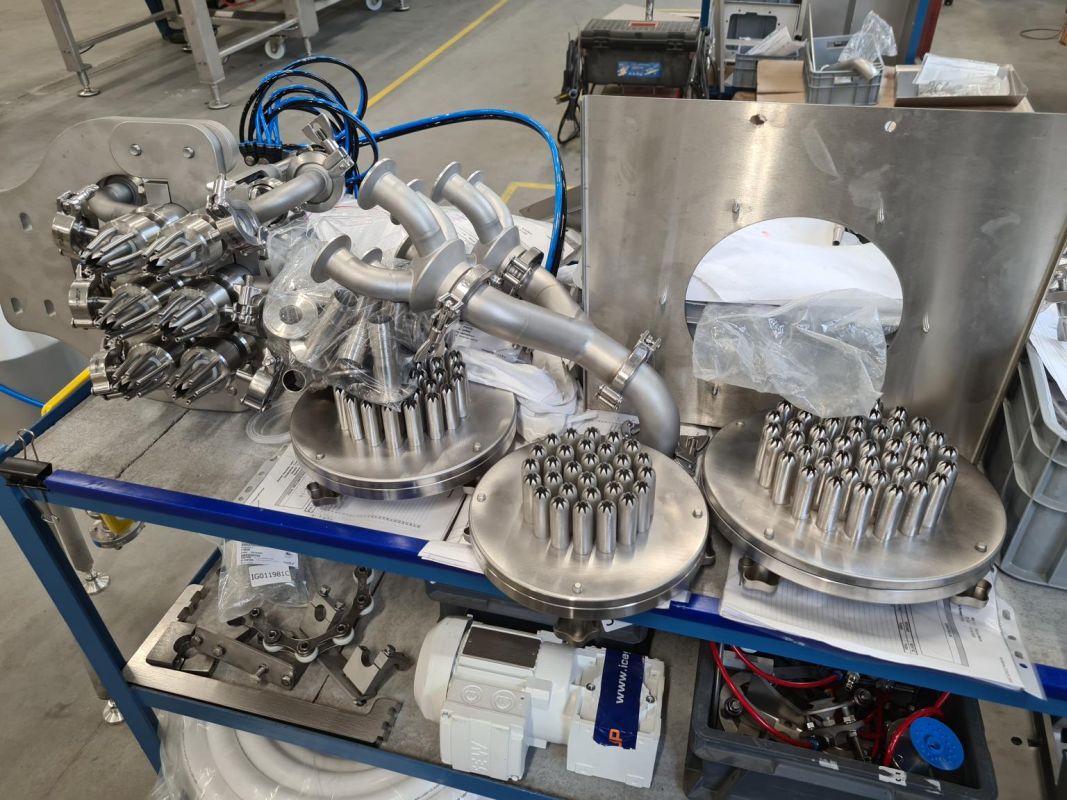

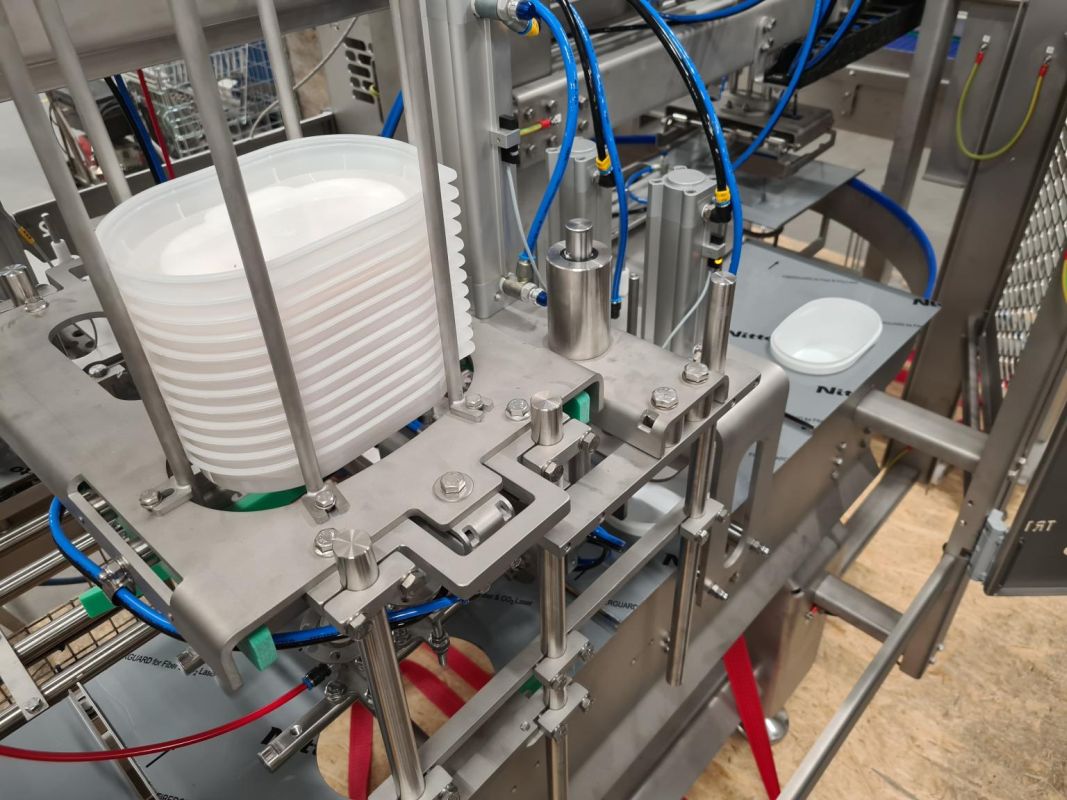

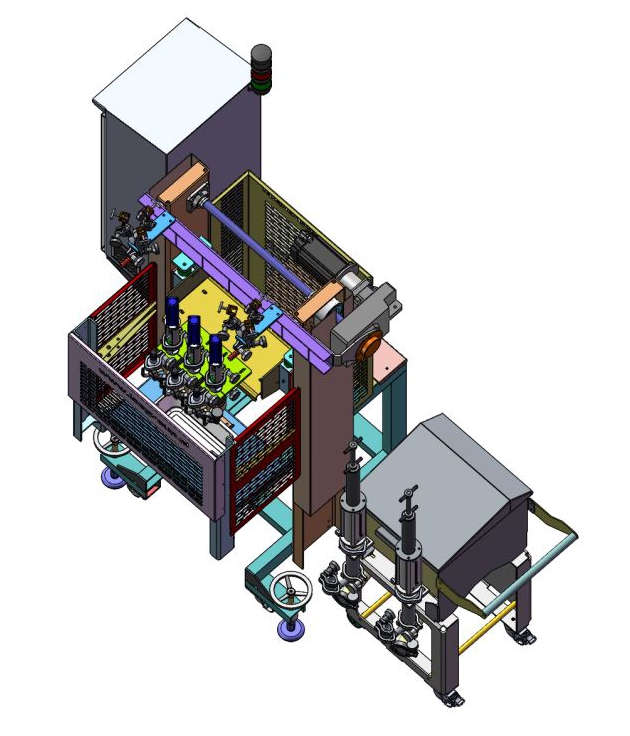

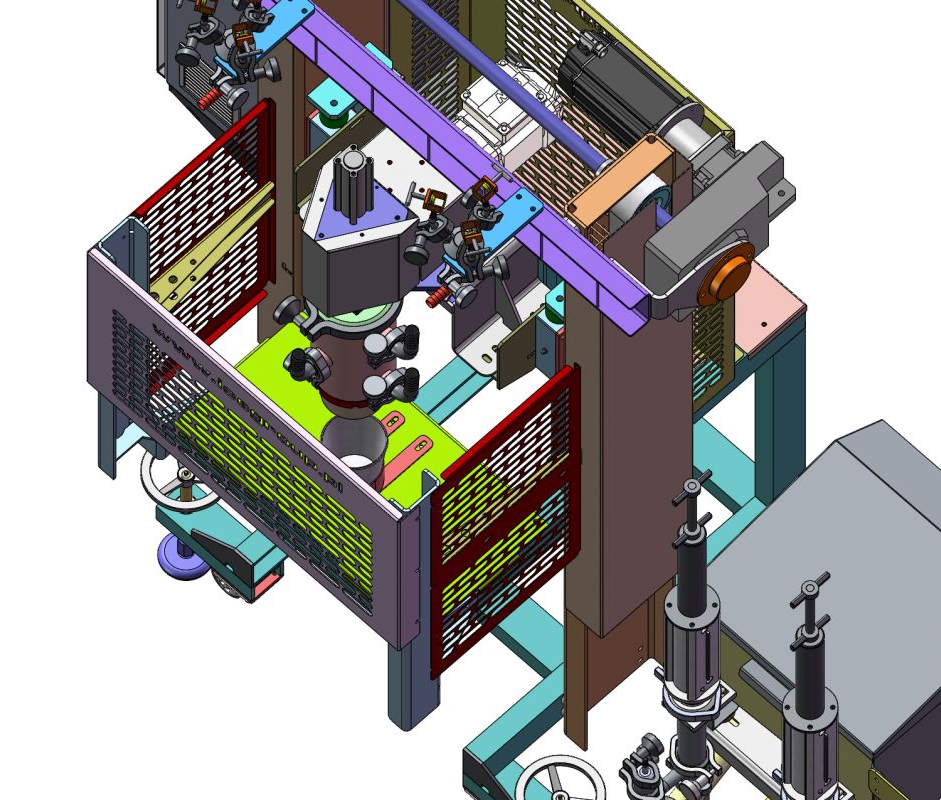

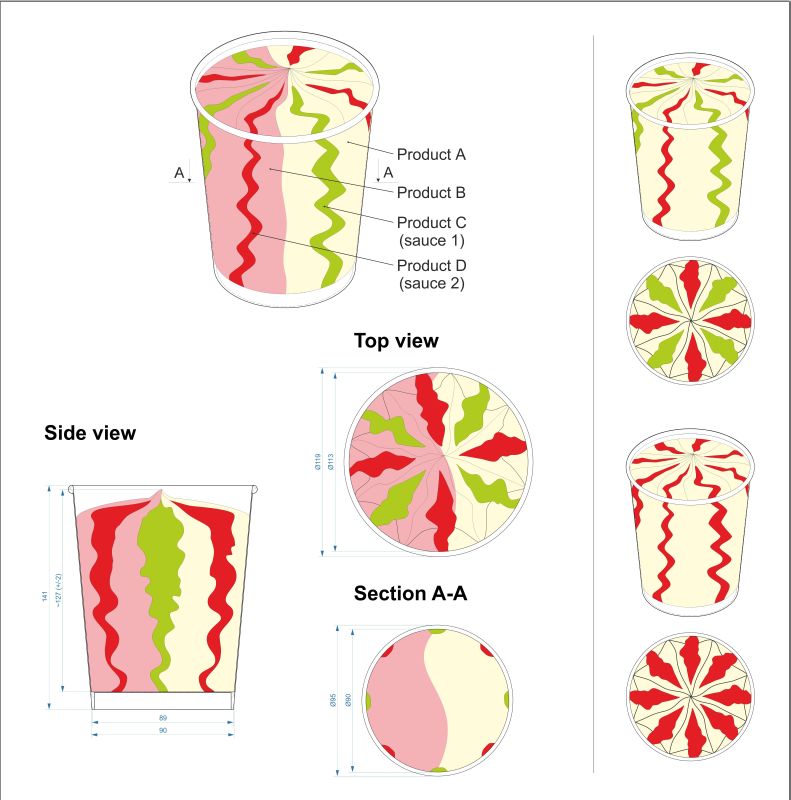

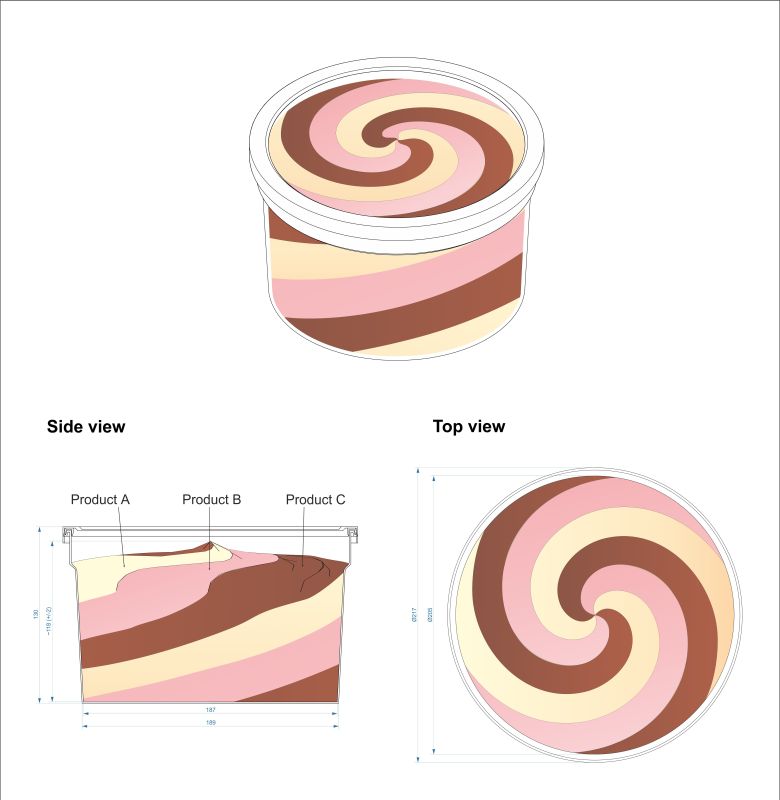

Ripple, syrup and chocolate pumps are underestimated, but often key components of deliveries on filling lines from the Expert or Jumbo Robot series, but also Iglo Line extruding and hardening tunnels for reaching an effect of sauce on the outside of the products (Star effect), inside the ice cream (e.g. Pencil filler), swirled like spiral or variegate, top decorating (topping), feeding and circulation of chocolate sprays and other.

This seemingly simple project has been transforming in our company for over 20 years, it’s been modified, upgraded, corrected and customized. Enough to say that currently, depending on the application and pumped product type we use:

- piston type pumps

- gear pumps

- screw (worm type) pumps

- lobe pumps

The second main component is the tank and here we have two basic categories – heated and non heated. Depending on the Customer’s needs, we have various sizes and divided tanks for two, three or more chambers.

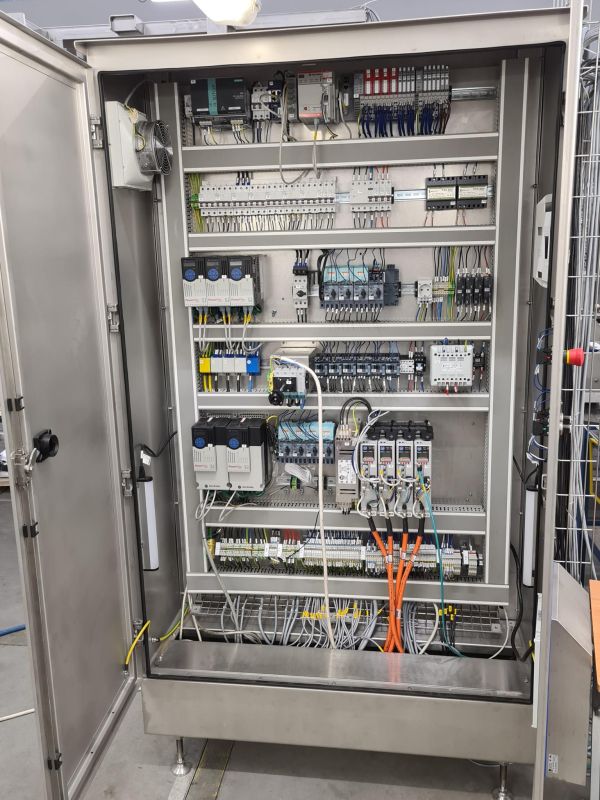

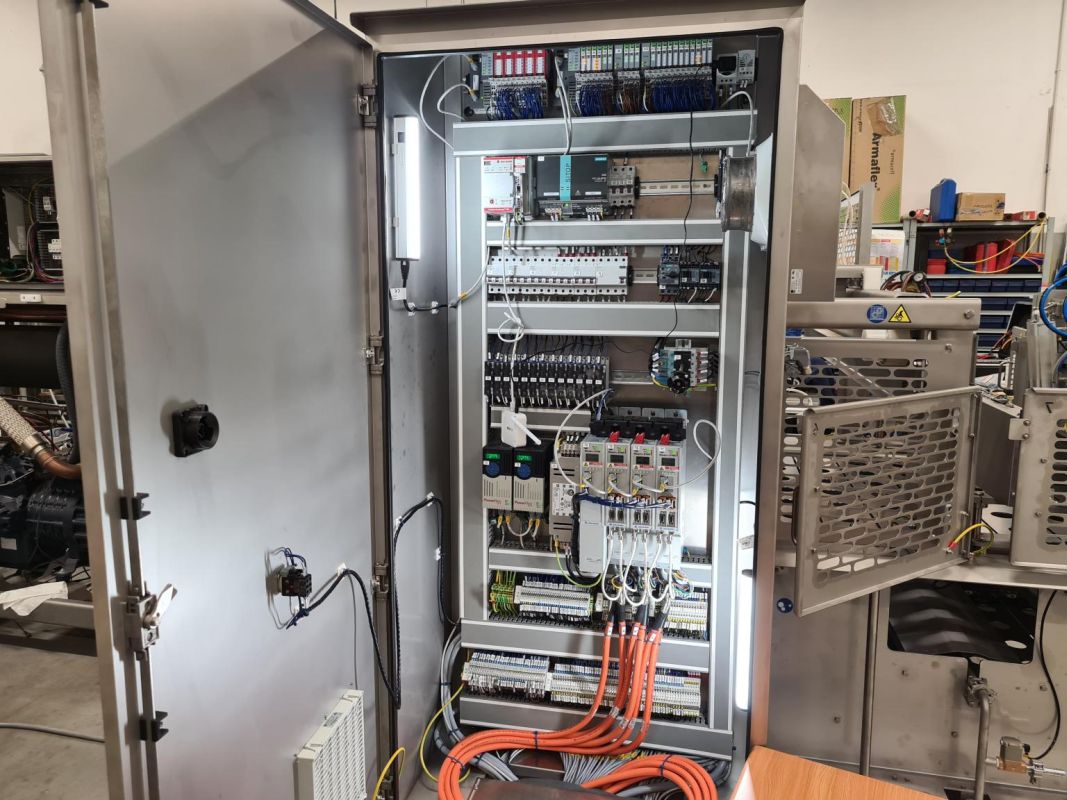

These units can be equipped with their own electric box with control elements, such as temperature, working cycles or frequency inverter regulators, or they can be without electric box, being a component of a line steered from the controller of the main machine, for example Expert CRF, LVF, Iglo Line.

This multitude of combinations has led to a situation in which our database of executed models has reached over 50!

We trust we can find the right solution for your application.